Phosgene guide

Phosgene, also known scientifically as carbon oxide dichloride, carbonyl chloride or carbon oxychloride, is the dichloride of carbonic acid. Its molecular formula is COCl2. At normal temperatures, phosgene is gaseous and extremely toxic. The substance, which was mainly used as a deadly chemical warfare agent during the First World War, has long been banned by the International Chemical Weapons Convention. In industry, phosgene is only used in closed circuits due to its high hazard potential.

History of phosgene

Phosgene was discovered in 1812 by the English physician, chemist and zoologist John Davy (1790 to 1868), the younger brother of the English chemist Sir Humphry Davy (1778 to 1829). He is best known for discovering the analgesic effect of nitrous oxide.

The name phosgene (Greek: produced by light) can be traced back to the photo-induced addition of chlorine gas to carbon monoxide carried out by Davy.

Properties of phosgene

Phosgene is a highly toxic colourless gas that is much heavier than air. Its sweet, foul odour, reminiscent of rotting banana peel or damp hay, is very characteristic and easy to identify. However, it is only perceptible at toxic concentrations, whereby the perceptibility quickly diminishes with heavy exposure.

Phosgene is highly soluble in organic solvents such as benzene, chlorobenzenes and toluene. In water, it gradually decomposes into carbon dioxide and hydrochloric acid. Therefore, anhydrous organic solvents must be used for its synthesis or conversion. Under the influence of short-wave UV light, phosgene decomposes into carbon monoxide and chlorine.

The molar mass of phosgene is 98.916 g/mol. The melting point is -128 °C and the boiling point is 7.6 °C. At 25 °C, the gaseous substance has a density of 4.03 g/litre. As a liquid at the boiling point, it is 1.4 g/cm3.

Production of phosgene

Phosgene is produced from carbon monoxide and chlorine using a catalyst consisting of activated carbon. The highly exothermic reaction requires extensive cooling, as the temperatures in the “hotspot” rise to up to 600 °C. Carbon monoxide is added to the reaction in excess to ensure the complete conversion of the chlorine and to counteract a chlorine-iron fire (exothermic reaction of chlorine and iron at more than 170 °C). To prevent the formation of chlorine oxyhydrogen gas, the carbon monoxide must be absolutely free of hydrogen.

Carbonyl chloride can also be formed when burning plastics containing chlorine (e.g. PVC) in the presence of metal and coal and when burning the refrigerant R22, which has been banned since January 2010 (e.g. when soldering old copper pipes of refrigeration systems filled with it). It can also be produced on a laboratory scale from tetrachloromethane and fuming sulphuric acid (oleum).

Health hazards of phosgene

Due to its poor water solubility, phosgene reaches the alveoli via the bronchi after inhalation without significant decomposition. It damages these in two ways. Firstly, part of the substance is decomposed by liquid due to the large contact surface. The resulting hydrochloric acid cauterises the surrounding tissue. Furthermore, SH, OH and NH2 groups of proteins and enzymes are acylated in the alveolar tissue (formation of thioester, ester and amide functions).

Which of these damage mechanisms plays the primary role depends on the phosgene concentration and the inhalation dose (product of the concentration and the inhalation time). Both effects contribute to the development of pulmonary oedema (accumulation of water in the alveoli). The extent of the damage depends primarily on the inhaled dose. Another important factor is the intensity of breathing. Physical exertion increases the toxic effect.

For safety reasons, the “phosgene indicator badges” worn by employees in phosgene-producing and processing plants therefore show the exposure dose instead of the exposure concentration so that adequate treatment can be initiated immediately in an emergency.

At low inhalation doses, those affected generally remain under medical observation for a few hours and receive precautionary therapy. Permanent damage is not to be expected in these cases. At higher installation doses (from approx. 150 ppm – min), pulmonary oedema usually develops within two to three hours, the extent of which depends on the respective dose. This severely impairs breathing. Oxygen uptake from the air we breathe into the blood is reduced. Without treatment, death by suffocation usually follows. In some cases, two to three days pass before death occurs. Very high doses can cause death within seconds to minutes, as the gas reacts with the proteins in the alveolar walls and can thus completely prevent gas exchange.

The health risk posed by phosgene is not so much due to its toxicity (sarin, novichok, tabun and other modern chemical warfare agents are considerably more toxic), but rather to the nature of its effect. Even those affected by lethal doses are often free of symptoms for hours, which means that medical countermeasures are often initiated too late. This problem is evident in all known fatalities in the industrial handling of phosgene. It is therefore essential to wear an indicator badge. Only the badge reliably indicates the dose taken to the attending physician.

With adequate treatment, pulmonary oedema caused by phosgene intoxication heals without further consequences in the medium and long term. Only in the first few weeks after exposure to the toxic substance is there a reduction in lung function, which gradually subsides.

Fatal accidents in connection with phosgene

Several fatal accidents occurred during the industrial production and processing of phosgene. The most serious of these occurred on 20 May 1928 in Germany. On the premises of the Stoltzenberg chemical factory (Hamburg), a valve on a tank wagon blew off for unexplained reasons, causing the phosgene it contained to change into a gaseous state at outside temperatures of 20 °C. The tank contained around 10,400 litres of phosgene, which was then released into the Müggenburg canal in the form of a toxic gas cloud. The tank contained around 10,400 litres of phosgene, which then spread in the form of a toxic gas cloud via the Müggenburg Canal towards Wilhelmsburg, where it entered residential areas. At least ten people died and a further 300 fell ill.

The last major accident in Europe occurred in the Bavarian capital in 2008. Fortunately, there were no fatalities. On 14 March, a hose of a test facility in a laboratory at the Technical University of Munich in Garching burst. This caused phosgene to leak out. Two people were taken to the intensive care unit with pulmonary oedema and a further 38 were examined in hospital as a precaution.

The last fatal accidents involving phosgene occurred in the USA in 2010 and in South Korea in 2016. On 23 January 2010, the sudden rupture of a steel hose connected to a phosgene tank on the premises of the DuPont Chemical Facility in Belle, West Virginia, led to the release of the toxic gas. One employee succumbed to the effects of exposure the following day. On 27 May 2016, a phosgene leak occurred at a BASF TDI plant in South Korea. A relative of a third-party company working at the plant inhaled phosgene and died as a result on 9 June 2016.

Between the accident in Hamburg in 1928 and the one in Dupont in 2010, there were other fatal accidents in the second half of the 20th century, most of which were publicised and investigated by the respective state authorities. A phosgene leak was initially suspected in the 1984 Bhopal disaster. However, this was clearly refuted.

Areas of application for phosgene

The main area of application for this substance is the large-scale production of aromatic diisocyanates such as toluene diisocyanate (TDI) and methylene diphenyl isocyanate (MDI). These are used, for example, in the manufacture of polyurethane-based foams and the production of polycarbonate (PC). The latter is required for the production of high-quality plastics. More than 90 percent of the phosgene produced worldwide (over three million tonnes per year) is used for this purpose.

Other uses include the production of “aliphatic” diisocyanates such as hexamethylene diisocyanate (HDI) and isophorone diisocyanate (HPDI), which are used to produce high-quality paints, e.g. automotive paints, and the production of monoisocyanates such as methyl isocyanate, which are used in the manufacture of crop protection products.

The use for the production of carboxylic acid chlorides and pharmaceuticals is of secondary importance in terms of quantity and economy. The same applies to the production and utilisation on a laboratory scale. The largest plants are located in Saudi Arabia, the USA, Germany, China, Japan and South Korea. The most important producers include DOW, the Bayer spin-off Covesto and BASF.

Due to its high toxicity, more than 99 per cent of the phosgene is produced in the same production plant where it is further processed. In this way, hazardous transport via internal company and public transport routes can be avoided. Interim storage is also avoided, as the carbonyl chloride produced is immediately turned into comparatively harmless downstream products.

A phosgene surplus is used for further processing. Unused surplus quantities are recovered and fed back into the production process. Residual quantities are absorbed by activated carbon and destroyed by hydrolysis with water. Alternatively, liquid diphosgene (trichloromethyl chloroformate) and solid triphosgene (bistrichloromethyl carbonate) are available in the laboratory, which have a similar reactivity but are less dangerous to use and less problematic to store.

Phosgene as a warfare agent

After Germany used chlorine gas for the first time in the Second Battle of Flanders at Ypres on 22 April 1915, phosgene was added to it in increasing concentrations as the war progressed. As soon as the German soldiers were equipped with protective masks, the use of phosgene as an admixture to chlorine gas became routine.

Later, the British also used chlorophosgene.

It is generally assumed that around 90,000 people died as a result of exposure to chemical warfare agents during the First World War, with Russia accounting for more than half of the deaths. Around one million soldiers suffered permanent damage to their health.

Safety measures when handling phosgene

Due to the health hazard it poses, phosgene must be labelled with the hazard symbol T+ (very toxic). In addition, the labelling R 26 (very toxic by inhalation) and R 34 (causes burns) are mandatory. The occupational exposure limit value is 0.082 mg/m³ or 0.1 ml/m³ in accordance with TRGS 900.

The following protective measures must be observed when handling phosgene manually:

- Good ventilation of the work area

- Extraction of vapours

- No smoking or welding

- Do not open valves with force

- When changing cylinders, check the valves of full and empty cylinders for leaks

- Avoid contact with skin, eyes and clothing at all costs

- Maintain personal hygiene

- Wear chemical protective gloves

- Use gas filter B (grey) for respiratory protection

- Always carry breathing apparatus with you so that you can flee quickly in the event of a phosgene leak

A competent person must always be present when phosgene is being filled. Supervision may also be carried out via a monitor from a permanently manned control room, provided that rapid intervention is guaranteed in the event of an emergency.

If phosgene has been inhaled, it is important to first ensure that the affected person is absolutely calm and to administer a spray containing cortisone via the airways as quickly as possible. It is also essential to consult specialised doctors who can initiate further medical measures if necessary.

Gas detectors minimise risks when handling phosgene

The insidious thing about phosgene is that it does not immediately cause symptoms when inhaled in small doses. In addition, the characteristic odour of the gas is generally only perceptible at toxic concentrations and is quickly lost again. It is therefore important to continuously monitor endangered areas using measurement technology in order to be able to take protective measures for the people working there in good time if necessary.

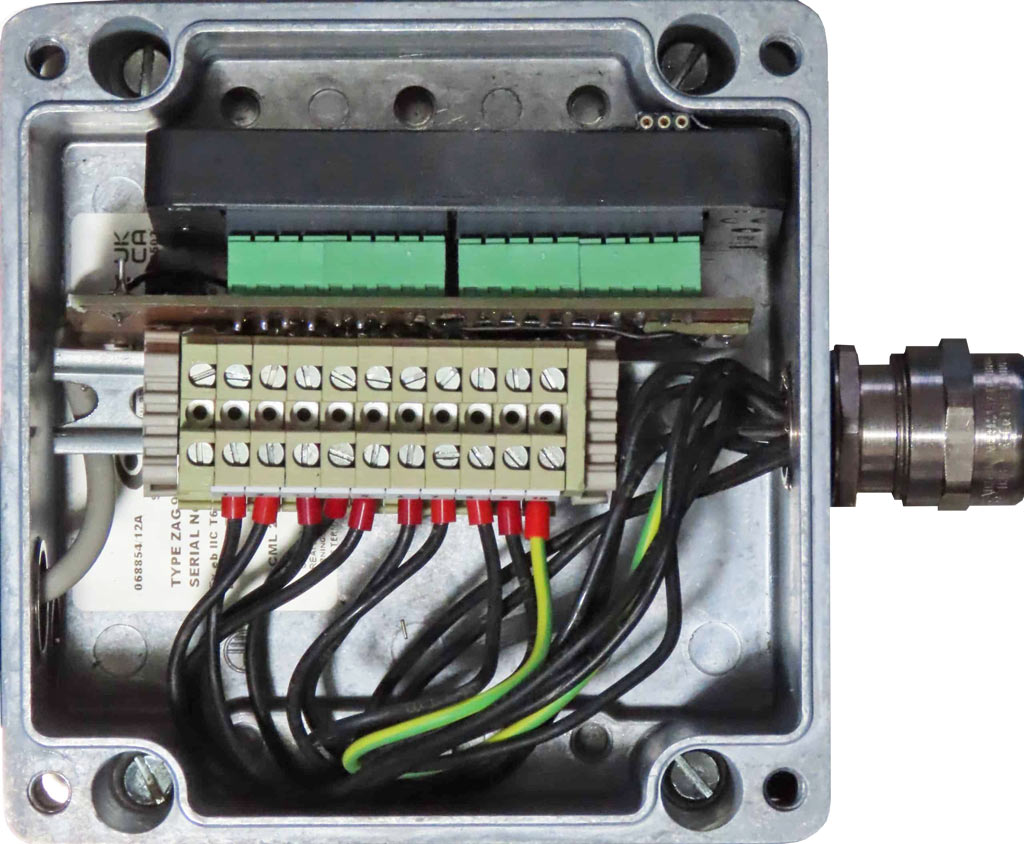

Compur Monitors has developed both stationary and portable electrochemical sensors and colourimetric systems that reliably warn of phosgene and other hazardous gases in the ambient air as soon as the specified limit value is exceeded.

The product range includes, for example, the mobile leak detector Tracer, which can detect phosgene in a range of just a few ppb. Compur also offers the Statox product family with various models tailored to the respective application. Particularly noteworthy is the Statox 560, which can test itself for good function with phosgene generated on board.

Source: Wikipedia

Dr. Josef von Stackelberg

Managing Director COMPUR MONITORS GmbH & Co. KG

Contact us without obligation

Do you have any questions about our products or would you like a non-binding consultation? We look forward to hearing from you.