Phosgene indicator badge MEDIC

Phosgene is gaseous at normal temperatures and is considered to be very harmful to health. This gas has a very bad reputation because it was used in World War I together with chlorine as combat gas. Many of us have terrible pictures of burned soldiers in our heads when the word phosgene is mentioned.

Nowadays phosgene is an important raw material in the chemical industry. Our current lifestyle would be as is without materials that require phosgenation to be produced. Just to mention a few examples: numerous drugs, polyurethanes (foams, adhesives, paints, insulating materials, upholstery…) and polycarbonates (CDs, mechanical car body parts, controls, housings…).

It goes without saying that the highest safety standards apply in the production and use of phosgene. Phosgene plants are monitored around the clock by highly sensitive measuring devices, so that even the smallest leakage will be detected before anyone can be harmed.

Phosgene exposure will not show immediate symptoms. Therefore personnel must be monitored for total exposure, in order to give the therapist accurate information which kind of therapy is appropriate when somebody has been exposed.

Despite all these safety precautions, no one can completely rule out the possibility that someone might have been exposed. Fortunately phosgene intoxication can be treated – provided the treating physician has exact information about the total exposure of the person.

A phosgene intoxication may be insidious, because it does not cause any immediate symptoms compared to other toxic gases. For this reason there is a risk that an employee who has been exposed might not be treated adequately, or might even be overtreated. The doctor must therefore know the total dose = concentration * time in order to decide on the right therapy.

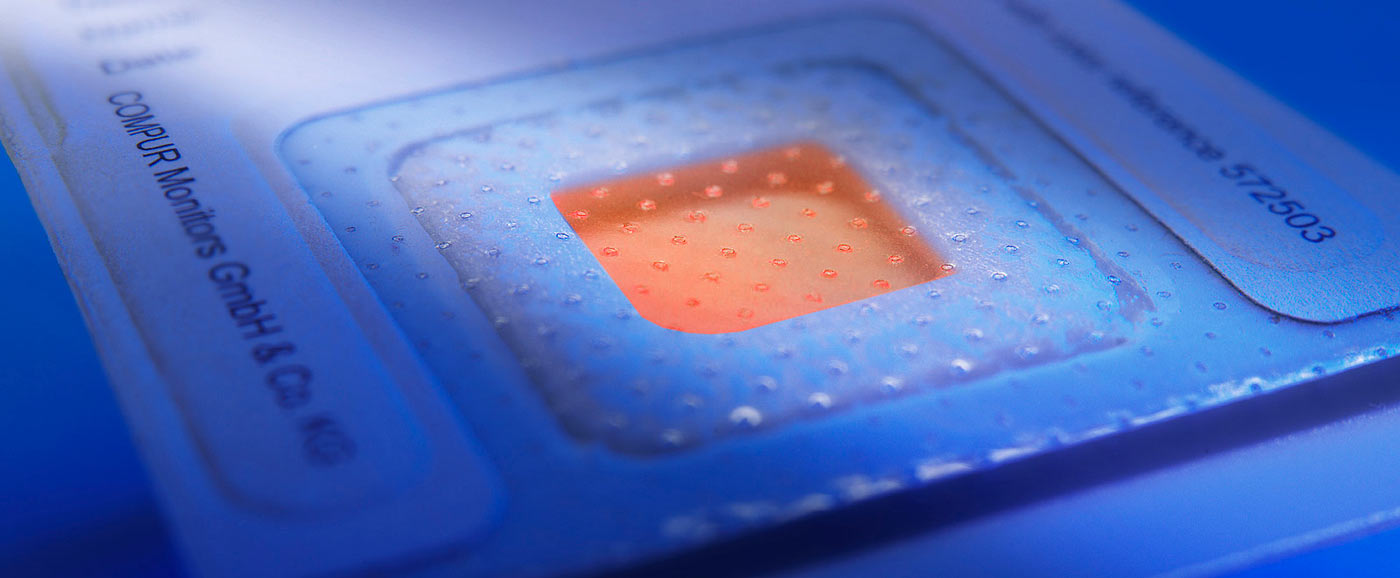

The Compur indicator badge MEDIC shows the total exposure exactly. It turns darker red the higher the total exposure has been. The sticker is compared with a colour standard on which the exact total dose = concentration * time in ppm * min can be read. With this tool – provided with the name of the user – the physician has all necessary information at hand in order to provide the exposed employee with the optimal treatment if necessary.

Quick navigation:

Technical data | Downloads

Technical data

| Gas to be detected | COCl2 |

| Range | 10 – 300 ppm * min |

| Dimensions | 72 * 44 * 4 mm / 2,8 * 1,7 * 0,015 in (h * w * d) |

| Material | PET, PE, Papier |

| Color Change | yellowish white to brick red |

| Operation Temperature | -20°C to +40°C / – 4°F to 77°F |

| Humidity | rel. Humidity 10 to 100 % |

| Usage | 1 min to 5 Days after Activation |

| Storage Temperature | + 2°C to 25°C / 35°F to 77°F |

Downloads

Attention! Only use the printed colour standard supplied with the product. Comparisons with images on a screen or your own prints may be not accurate. Please always dispose of your old standards when opening a new box, as colours on a printed matter might fade.

Dr. Josef von Stackelberg

Managing Director COMPUR MONITORS GmbH & Co. KG

Contact us without obligation

Do you have any questions about our products or would you like a non-binding consultation? We look forward to hearing from you.