New battery technology requires intensive testing

In future more and more automobiles shall have electric motors. Drivers will appreciate battery driven cars only, if they are 100 % suitable for dayly use. Therefore innovative, robust and safe energy storage devices with high capacity are needed. Todays most used batteries contain Lithium. Transportation of more than 3 g respectively 0,1 oz Lithium is regulated, because Lithium is a very reactive element. Before car industry incorporates half a ton of Lithium batteries into a vehicle, this battery must undergo severe endurance testing.

No wonder industry is strongly investing in battery development and battery testing. Before a battery goes onto the street it must prove that it can endure all kinds of stress: Heat, mechanic stress, electric stress, aging…

Stress testing means, the specimen may be destroyed. A destroyed Lithium battery can release as well toxic as explosive gases. In order to protect personell and environment, some of the testing stations must have a gas detection system.

In order to quantify the risk, there is the so called EUCAR Hazard Standard. EUCAR (European Council for Automotive R&D) classifies the risk by defining the potential impact on people and environment. The highest risk class requires a gas detection system to be on board.

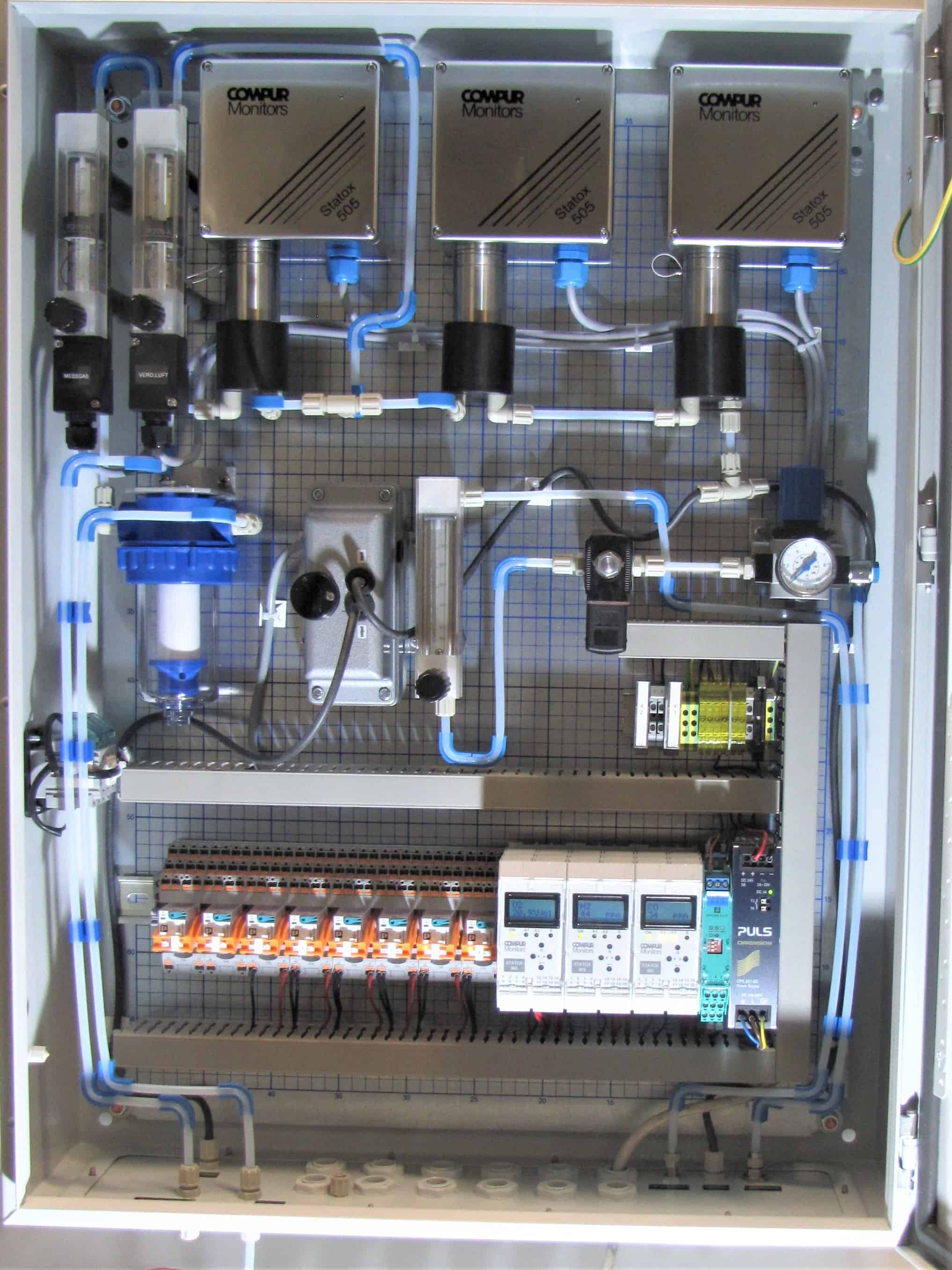

In cooperation with the car industry Compur Monitors has devlopped an extractive gas detection system suitable exactly for this application.

Testing of Car Batteries

The use of batteries in vehicles requires utmost safety and robustness. Therefore prototypes and specimen of the running production must undergo intense testing. Battery testing stations consist of two components. The testing compartment itself – this can be a metal table, a separate room or a container, and a control device, normally a laptop or computer. For safety reasons these two components are located in separate rooms.

The most important component is of course the testing station itself. Here the specimen can be exposed to electrical, mechanical and / or heat stress. The measured values are transmitted to the control device, where they are evaluated and stored. It is essential that the control device is in a separate room, because batteries stressed to the limit can be very dangerous.

As an option there can be extra safety installations such as access control devices, locking systems, gas detectors and automatic extinguishing systems.

FAQs

Testing of Car Batteries

The use of batteries in vehicles requires utmost safety and robustness. Therefore prototypes and specimen of the running production must undergo intense testing. Battery testing stations consist of two components. The testing compartment itself – this can be a metal table, a separate room or a container, and a control device, normally a laptop or computer. For safety reasons these two components are located in separate rooms.

The most important component is of course the testing station itself. Here the specimen can be exposed to electrical, mechanical and / or heat stress. The measured values are transmitted to the control device, where they are evaluated and stored. It is essential that the control device is in a separate room, because batteries stressed to the limit can be very dangerous.

As an option there can be extra safety installations such as access control devices, locking systems, gas detectors and automatic extinguishing systems.

What happens when a battery is destroyed?

Lithium is a very reactive element. If a Lithium ion battery is stressed over the limit by mechanical damage, heat or electrical stress, it may release toxic or explosive gases or vapors. Therefore battery testing must not be done without appropriate safety precautions. It is highly recommendable to discuss eventual extinguishing measures with a specialist of the fire brigade.

Why can Lithium-batteries explode?

In day to day use a lithium cell will not explode, because it is encapsulated in a sturdy metal cylinder. But if it is stressed to the limit, a so – called thermal runaway may happen. In this case it can heat up to several hundred degrees and thus destroy itself completely. This heat release may even destroy neighbored cells, which will also produce a high amount of energy. This chain reaction can make the complete array of cells – for instance a car battery – explode.

Exactly this is reason for the intense testing of batteries. If the battery is damaged by heat, an accident or a defective charger, it must not explode and probably hurt or even kill people.

In practical use you should not use a Lithium battery if it shows mechanical damage, heats up, smokes or is even outgassing. Put it into a container with a high volume of water to cool it down and then dispose it. If a big battery like a vehicle battery is damaged, go away as fast as you can and alarm the fire brigade.

Which substances can be released by a damaged Lithium battery?

As said, under normal use all the chemicals are sealed in the cell capsule. But as soon as a cell is damaged, or has a manufacturing defect, an overpressure might develop to which the capsule cannot withstand.

The electrolyte consists of linear and cyclic carbonates, solvents and conductivity salts. These chemicals are volatile, corrosive and combustible. In ambient air they may even produce an explosive mixture. The salts are not volatile, but together with liquids they may develop hydrofluoric acid which is very toxic and extremely corrosive.

If the cell heats up at the same time, ethane, methane, butane, propane and aldehydes may be released. This atmosphere is toxic and explosive, a real danger human health and assets.

Entnahmesystem mit eingebauter Pumpe für CO, H2 und Sauerstoff.