We wrote history – not only in gas detection

Find out more about the history of Compur – from 1898 to today …

…might the first settlers on mars find an old fashioned space camera, that has been hidden in the dust, since 1971? They will wonder how this antiquity can carry the same brand name as the air quality control of their space ship: Compur…

Compur introduces a revolutionary communication system for the Statox 560: Now both the measured value and the numerous status messages can be transmitted via a two-wire line. A self-test can even be triggered manually.

On 1 January 2023, one of the managing directors, Bernd Rist, leaves the company to retire. Dr Josef von Stackelberg takes over his role.

A completely new product family is being added: The Statox 506: This product line comprises a comprehensive range of highly selective field-tested electrochemical plug and play sensors. SIL 2 standard.

A completely new product family is being added: The Statox 506: This product line comprises a comprehensive range of highly selective field-tested electrochemical plug and play sensors. SIL 2 standard.

The Statox 560 gives you the ultimate safety in gas detection: It self tests itself with the target gas in programmable intervals.

The Statox 560 gives you the ultimate safety in gas detection: It self tests itself with the target gas in programmable intervals.

The new Statox 503 control module can handle all kinds of gas detectors and other front ends. Instrument specialists love this allrounder which complies with SIL 2 standard.

The new Statox 503 control module can handle all kinds of gas detectors and other front ends. Instrument specialists love this allrounder which complies with SIL 2 standard.

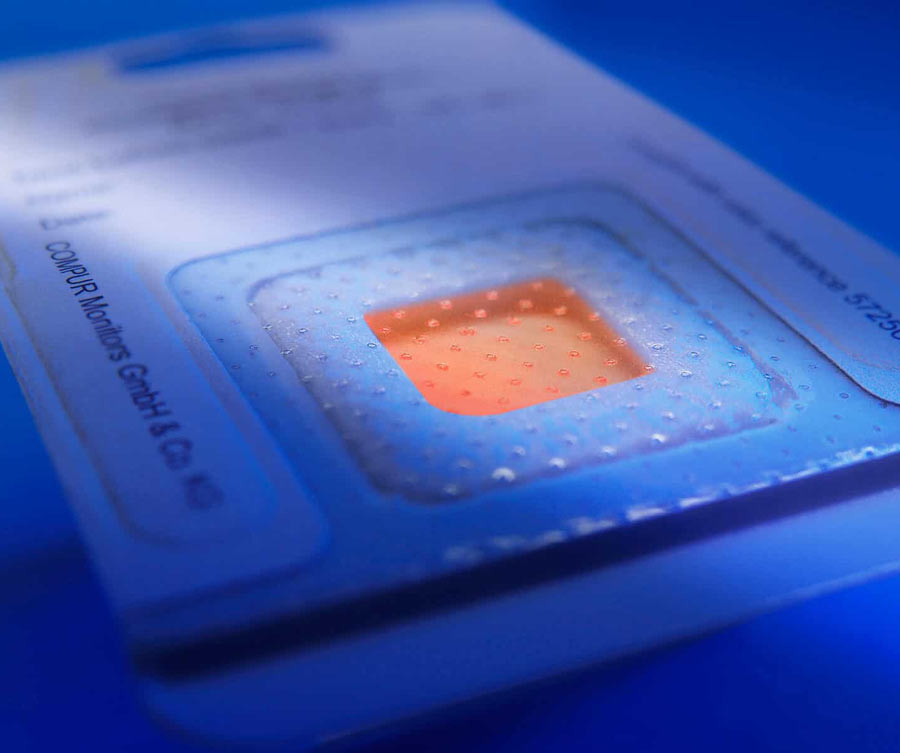

The new Phosgene Indicator Badge MEDIC, developped to the latest knowledge of industrial hygiene, conquers the market

The new Phosgene Indicator Badge MEDIC, developped to the latest knowledge of industrial hygiene, conquers the market

Toxic gas detector Statox 505 sets the standard for modern gas detection technology. It is one of the first gas detection systems that complies with Sil 2 standard.

Toxic gas detector Statox 505 sets the standard for modern gas detection technology. It is one of the first gas detection systems that complies with Sil 2 standard.

Statox 501 IR comes to the market. This gas detector sets the benchmark in terms of reliablity and ruggedness.

Statox 501 IR comes to the market. This gas detector sets the benchmark in terms of reliablity and ruggedness.

Statox 501 is introduced to the market. It was a success story right from the start . One of the first systems not requiring a rack, it reduced the system price of a gas detection system significantly, and thus got the sympathy of the users. The memory of the control module holds enough programs to operate a variety of sensor heads with different sensor technologies. The future started here!

Statox 501 is introduced to the market. It was a success story right from the start . One of the first systems not requiring a rack, it reduced the system price of a gas detection system significantly, and thus got the sympathy of the users. The memory of the control module holds enough programs to operate a variety of sensor heads with different sensor technologies. The future started here!

After one year being a daughter company of Hartmann and Braun, Compur Monitors GmbH was founded, a company focussed on gas detection for your safety.

Six years later Compur becomes a daughter company of Bayer AG. The department Compur Monitors specialises in gas detection and process analysers. Many product families, fixed and portable, come to the market. If in an Australien goldmines or in a waist water station in Bavaria: All over the world people trust in the safety of Compur products.

Six years later Compur becomes a daughter company of Bayer AG. The department Compur Monitors specialises in gas detection and process analysers. Many product families, fixed and portable, come to the market. If in an Australien goldmines or in a waist water station in Bavaria: All over the world people trust in the safety of Compur products.

Since 1978, the Compur Monitors R & D department has developed sensors and instruments for the detection of toxic and combustible gases. The basic design of these sensors goes back to the engineering department of Bayer. This part of the long Compur tradition is the root from which Compur Monitors has emerged. After having become a fully owned subsidiary of Bayer AG in 1986 the now privately owned company “Compur Monitors GmbH & Co KG” was finally founded in 1994.

Since 1978, the Compur Monitors R & D department has developed sensors and instruments for the detection of toxic and combustible gases. The basic design of these sensors goes back to the engineering department of Bayer. This part of the long Compur tradition is the root from which Compur Monitors has emerged. After having become a fully owned subsidiary of Bayer AG in 1986 the now privately owned company “Compur Monitors GmbH & Co KG” was finally founded in 1994.

In 1976, Bayer AG acquires a 50% stake in the company and contributes numerous ideas from its engineering department.  Further products are quickly developed: An electronic ampoule tester and numerous measuring devices for medical diagnostics as well as miniphotometers for wastewater monitoring. At the same time, the first electronic answering machine, the Alibiphon, is developed. The company is now logically called Compur Electronic

Further products are quickly developed: An electronic ampoule tester and numerous measuring devices for medical diagnostics as well as miniphotometers for wastewater monitoring. At the same time, the first electronic answering machine, the Alibiphon, is developed. The company is now logically called Compur Electronic

In 1971 a device called “picture watching machine” was developed. It worked similar to the now well-known video. As a consequence, Carl Zeiss bought the company. During this time Compur made optical analysers for medical applications, a testing machine for ampoules, and the first answering machines. When the shutter business finally ceased, a joint venture with Bayer AG started.

Immediately after the Second World War, the reconstruction of the factory begins on the orders of the occupying power under provisional management. By the time of the currency reform in 1948, production was already running at full speed. Camera shutters are now predominantly manufactured. In 1951, the Synchro-Compur is launched on the market. It would set the standard for precision in photography for another quarter of a century. As proof of this, the first Zeiss cameras to deliver images from space as part of the Gemini programme were equipped with shutters based on the Compur principle. Zeiss acquires the Compur factory in the mid-1950s. This is synonymous with the entry into the age of electronics.

Immediately after the Second World War, the reconstruction of the factory begins on the orders of the occupying power under provisional management. By the time of the currency reform in 1948, production was already running at full speed. Camera shutters are now predominantly manufactured. In 1951, the Synchro-Compur is launched on the market. It would set the standard for precision in photography for another quarter of a century. As proof of this, the first Zeiss cameras to deliver images from space as part of the Gemini programme were equipped with shutters based on the Compur principle. Zeiss acquires the Compur factory in the mid-1950s. This is synonymous with the entry into the age of electronics.

The Compur requires a level of manufacturing precision that cannot be achieved with standard machines on the market. So Deckel starts building tooling and engraving machines. Initially for the company’s own use. After the First World War, these machines were the first to be offered at the Leipzig Trade Fair. The war brought the market for camera shutters to a standstill. People had other things to worry about than taking pictures.

In 1911, a clock was added to this shutter, called “Compur shutter”, a design which is nowadays still used in the famous Hasselblad cameras. The name “Compur” is a combination of the words “Compound” for the central shutter and the German word “Uhr” for clock. This expression was used, as the shutter could now stay open for an adjustable time: it worked with the precision of a clock. This technology was state-of-the-art until the 70´s when film material with a higher tolerance to light exposure variations came onto the market.

The weak point of these cameras was the shutter, as there was no possibility to adjust the exposure time. Therefore it was impossible to take snap-shots. The photographic results were more or less accidental depending on the duration of the manual opening of the box – despite the fact that the light sensitive material itself was already good enough to take good pictures. Consequently in 1902 Deckel developed the first mechanic central shutter, called the “Compound” shutter. This shutter opened and closed the light access rapidly driven by a spring.

The weak point of these cameras was the shutter, as there was no possibility to adjust the exposure time. Therefore it was impossible to take snap-shots. The photographic results were more or less accidental depending on the duration of the manual opening of the box – despite the fact that the light sensitive material itself was already good enough to take good pictures. Consequently in 1902 Deckel developed the first mechanic central shutter, called the “Compound” shutter. This shutter opened and closed the light access rapidly driven by a spring.

Compur Monitors GmbH & Co. KG

Originally the company was founded by Friedrich Deckel in 1898 as a small back alley mechanical shop in Munich.

In the very beginning Deckel had to accept any odd job just to survive, but his real ambition had always been to develop and manufacture his own products. The opening of his shop in downtown Munich coincided with the beginning popularity of amateur photography. The first “travelling cameras” came onto the market – simple boxes made of polished wood. In these boxes a coated glass plate was exposed to light focussed by a lens.

Dr. Josef von Stackelberg

Managing Director COMPUR MONITORS GmbH & Co. KG

Contact us without obligation

Do you have any questions about our products or would you like a non-binding consultation? We look forward to hearing from you.